liquid painting

Our core expertise is in application of liquid coatings to aerospace, military, and commercial hardware. We apply epoxies, polyurethanes, enamels, lacquers and nearly any other liquid coating you might need.

Dry Film LuBRICANTS

We can apply all dry lubricant coatings to your parts per your engineering specifications. We routinely apply Teflon, graphite, molybdenum disulfide, titanium disulfide and many others for low friction and wear resistance in critical part locations.

powder coating

Our powder coating system includes a hanging parts conveyor that directly connects our paint booths to our large curing oven allowing continuous part coating and eliminating part handling after powder is applied. We routinely use polyesters, epoxies, nylons, vinyl, Kynar, Halar, Teflon and many other types of powder.

casting Impregnation

Large castings can be impregnated in our vacuum chambers with an approved sealant. The dry vacuum impregnated castings are thoroughly cleaned and cured to fabricate a perfectly sealed casting that will pass high pressure testing.

precision Masking

Our precision masking team uses multiple types of tapes, pre-cut forms, plugs and masking fixtures, as needed, to maximize through-put. We use our masking plotter to cut highly customizable masking for any finishing task.

high temp curing ovens

Our curing ovens operate at designed temperatures up to 800°F. Each furnace is carefully surveyed and calibrated as required. Records for process controls and lot testing are always available.

vapor degreasing

For parts that require superior cleaning, we offer TCE-based vapor degreasing. Vapor degreasing eliminates any dependence on operator cleaning methods and eliminates any possibility of contamination from other parts.

ultrasonic alkaline cleaning

For parts specifying alkaline cleaning processes, we use a fully-automated, high-power ultrasonic alkaline cleaning system.

sandblasting

Our large sandblast cabinets operate with various types of media. Metal prepping, cleaning and descaling are done with Garnet while the more delicate work is abrasive blasted with glass beads. Our plastic media is used for precise remove of paint from undesired areas.

dip Plastisol coating

Dip Plastisol is a thermoplastic polymer protective coating. We regularly apply Plastisol coatings to our customer’s parts and can accommodate a variety of part sizes and shapes.

silk-screen Printing

We can apply multi-color silk-screen printing to your parts to meet your specifications. Whatever serigraphy needs you may have, we can develop an efficient solution.

part marking

We have a variety of part marking capabilities that can be used to identify each part per your specifications.

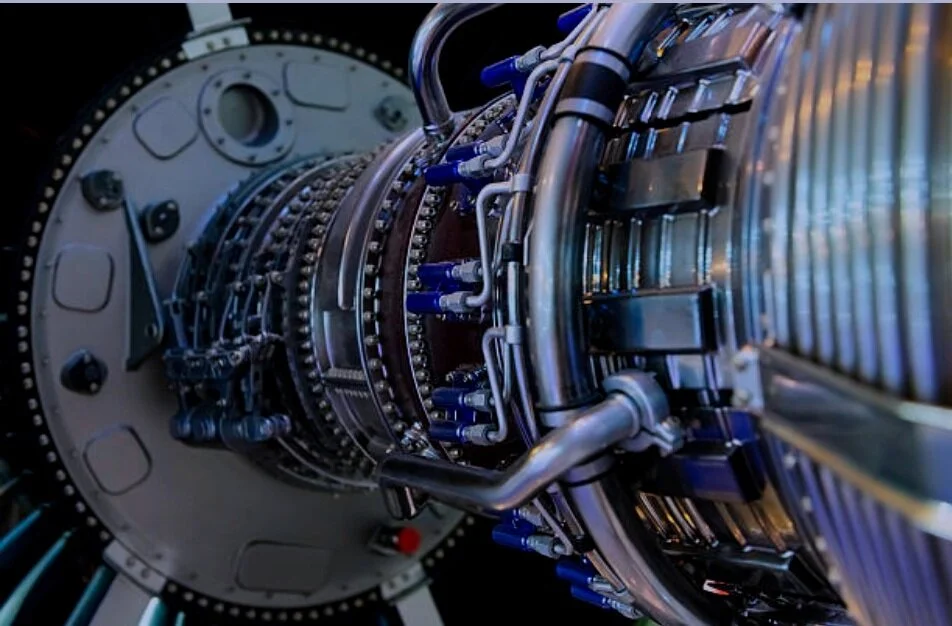

metal-ceramic coatings

We can apply many types of high temperature ceramic coatings to your parts, such as SermeTel W, in accordance with your engineering specifications.

chemfilm touch-up

We can expertly apply Alodine touch-up to your parts whenever required either as a stand-alone service or in preparation for an additional finishing process.

Part Pick-up & delivery

We can pick-up and deliver your parts on a daily basis for those customers in the greater Phoenix metro area.

Coming Soon…

Our goal is to provide you with a one-stop shop for new surface coatings and we are rapidly expanding our portfolio of processes. Our passivation and ChemFilm lines will soon be Nadcap certified and ready for production.

CHEMFILM

Our new ChemFilm line is capable of processing your parts per Type I & II, and Class1A & 3 chromate conversion methods. We offer all required pretreatments such as alkaline cleaning, etching, and deox. Our tanks are large enough to handle parts that fit within a 24”x24”x36” box. We constantly monitor the chemistry of each of our tanks to ensure every part is processed under strict quality control standards and according to your exact specifications.

Passivation

Our new fully-automated Passivation line is capable of passivating parts following both nitric and citric methods. Our fully-automated line ensures exacting quality control with each process step. Our processing tank also uses high-powered ultrasonics for agitation during the cleaning, passivating and rising process steps to improve the efficacy of each operation.